Kingshott books and videos were produced in the 1990s, and I still find them to be an invaluable source of information. Today I purchased his book The Workshop: Designing, Building, Equipping Paperback – 1 March 1994. You can’t find it on Amazon but I did find it on Abesbooks, and it was only US$2.75 plus postage so it worked out to be about AU$26.

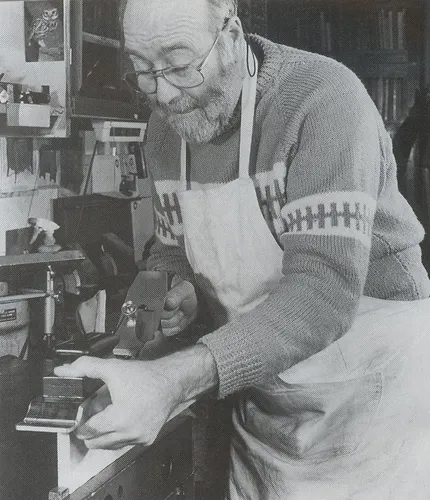

You may be wondering who this character is, right? Well, he was a master cabinetmaker, even though I don’t like to use the term “cabinetmaker” as the term is more in reference to those who make kitchens. He made furniture, and he was darn good at it too. His name wasn’t Jim; he was born Raymond John Kingshott on January 7, 1931, in England.

He grew up amongst woodshavings at his grandfather’s workshop. He was apprenticed as both a carpenter and furnituremaker in the 1940’s at A. J. Tracey & Co. Ltd., making him one of the last individuals to emerge from the system prevalent before World War II.

For over 50 years, Jim worked in the woodworking industry, making everything from coffins to aeroplanes, and until recently, he was apprentice master to the woodworking trade apprentices at the Royal Aircraft Establishment at Farnborough.

Jim’s forte was the making and use of handtools. He was a true master craftsman and probably did more to encourage traditional woodworkers in the UK than anyone else. He wrote and made several books and DVDs in the 1990s. One of the DVDs I was lucky enough to find on YouTube.

The book I purchased and mentioned above is one I’m looking forward to reading. I’ve never been satisfied with the layout of my workshop, and I’m hoping to gain some good information to help me out.

He has about ten books he’s written, and I will provide the link to them here: https://www.goodreads.com/author/show/955208.Jim_Kingshott

You cannot buy from the link provided, but if you search the title, some of them are still available. There are three books of interest that I’m eager to get my hands on: “Making & Modifying Woodworking Tools,” “Sharpening,” and “Woodworker’s Guide to Joints: An Illustrated Guide That Really Shows You How to Make Perfect Joints by Jim Kingshott (June 27, 1), paperback. The last one is more out of curiosity to see just how Jim executed each joinery technique by hand. I’m sure there will always be something new to learn.

For over 50 years, Jim worked with wood, from making coffins to aeroplanes. Had he still lived today, he would be 80 years in the trade.

Jim died on February 25th, 2002, after a long battle with cancer.

Jim’s grandson, Allan Kingshott, followed in Jim’s footsteps and is a qualified carpenter/joiner. So the family tradition of working wood continues.

His videos on dovetail and mortise/tenon were fundamental for me. Both videos include some wonderful asides where he talks about life in a working shop. “Oops, I’da got fined sixpence for that, in the old days!”

LikeLiked by 1 person

lol yes, I just love the sunlight tax. If you a workshop with a window and the light from the sun shone into your workshop they would tax you for it. I just don’t know how they got away with it. Had it been France it would have been total destruction and beheadings.

LikeLiked by 1 person

Just this past weekend I saw a video on YT with him describing all the different hand planes. I loved his way of talking and working. I gotta check out his other stuff.

LikeLiked by 1 person

Yeah, I’ve seen one that too a couple of years ago. It left me wondering about the big Norris jointer he had what would it feel like to use. The weight does it really play any significant role? I wish he made many more videos, especially build videos. Last night I watched his half-lap dovetail video and saw him first pare the corners down. That made so much more sense to me.

LikeLike

Thanks for sharing that. I think that a master with a lifetime of experience might have quite something to offer, although I’ve learned much from online current younger experts.

LikeLiked by 1 person

Yes, it is good to learn from the old timers, but unfortunately, most have passed away.

LikeLike

I own the Making and Modifying Woodworking Tools. More about making tools than modifying old ones. It was a pretty good book, but I needed money and sold it. I wish I didn’t.

LikeLike

It’s a pity you sold it, I take it you didn’t get very much for it.

LikeLike

I can’t remember it was so long ago but I’m sure it was for less than $40.00

LikeLiked by 1 person

I have the Making and modifying book and set about producing the Norris style Jointer, every bit by hand and a mini lathe. I got a local farrier to heat treat and temper the iron( made from O1 gauge plate). When I filed the dovetails down I did not know about curved riffler files so scratched up the brass sides, I will have some engraving done to hide my mistakes. does it work? you bet it does!

LikeLiked by 1 person

Congratulations on your build. It is a very satisfying feeling when you build a tool and it works as it should.

LikeLiked by 1 person